HyL process

There are 3 different HyL process in the industries. Today one of them, HyL lll is more used in the industries as following:

HyL l

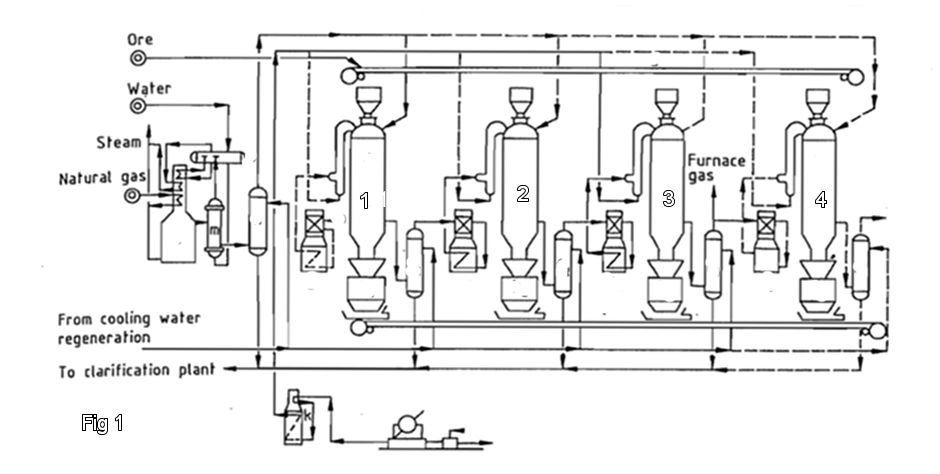

This process built up to 1975 before the shaft=furnace process became established .The process was developed in 1951 at Hojalata y Lamina S.A., Monterrey (Mexico). It operates with four reactors simultaneously, each one being at a different point in the reduction cycle at a particular time. We can consider the four stages as following(fig 1):

- Retort 1: The product DRI is cooled with cold reducing gas in retort 1.At this point, the carbon content of DRI is adjusted to ca.2% .After cooling and water-vapour condensation, the off-gas from this retort is reheated to reduction temperature and passed through retort 2

- Retort2: In this stage the pre-reduced material is fully reduced. The gas is then recooled to remove any newly formed water vapour, reheated and fed to retort 3

- Retort 3: In this stage freshly charged ore is then pre-reduced. The off-gas from this stage is cooled and freed from water vapour; it is then available for use as fuel gas for steam raising.

- Retort4: In this stage the DRI is simultaneously emptied and charged with lump ore or pellets

HyL ll

HyL ll is the Development process of HyL l where the following sources are changed:

- use high temperature alloy tube in the reducing gas reheating furnace, which permits heating the gas to the higher temperature

- second reduced the number of heating furnace for the original four units to two units.

In the HyL 2 process reducing gas (rich in CO and H2) is generated, typically by nickel based catalytic reforming.

HyL lll

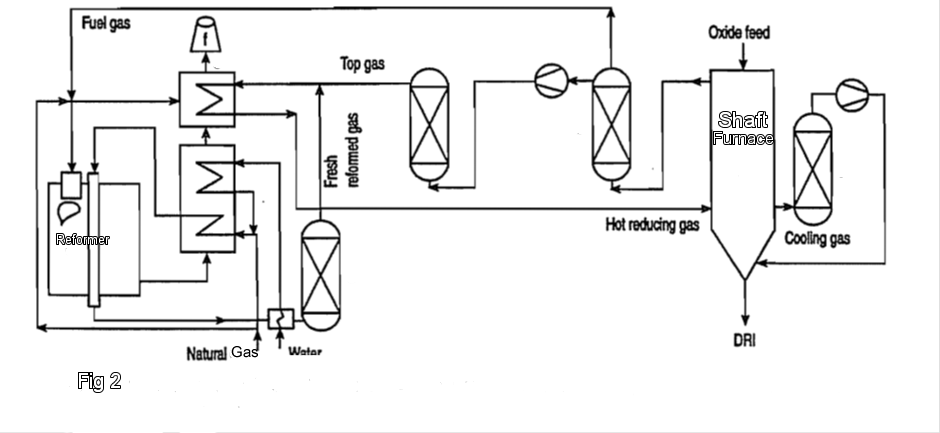

HyL lll is a single shaft furnace with a moving used in place of the four original fixed bed reactors. The main equipment of HyL lll comprises a DR shaft furnace, a gas reformer, and a gas reheated(fig2). The principles of operation of the furnace are similar to the midrex shaft furnace.

For more information please contact us.