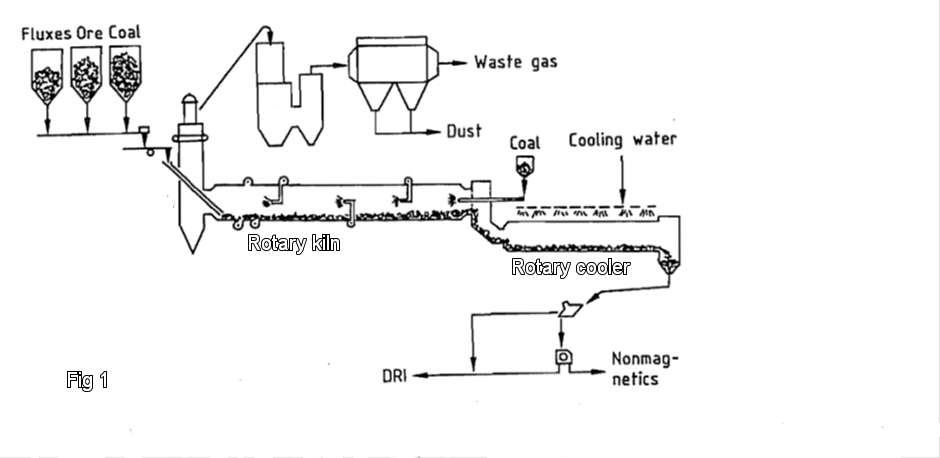

SL –RN process

Rotary kiln processes for direct reduction of iron oxides are based on coal as reductant. Of the various rotary kiln process the Krupp Codir process and Lurgi SL/RN process have attained the greatest technological significance. The two processes operate according to similar principles. The most of DRI currently produced in rotary kilns, which worldwide is manufactured by the SL-RN process.

SL-RN process

The SL-RN process was developed in 1964 out of the combination of two separate processes: the Stelco ¬–Lurgi (SL)(for process beneficiation high grade ores) and Republic Steel National Lead (RN) for process beneficiation low grade ores).

In the SL/RN process (fig 1), reduction of iron oxide is carried out in a refactorylined rotary inclined from the feed to the discharge end. The slope of the kiln is ca.1.5-2.5 % depending on the feed materials. The process uses lump ore, pellets, beach sand or ilmenite ore and solid carbon to produce hot or cold DRI. The kiln is equipped at both ends with special seals between the rotating kiln and the fixed feed and discharge heads. These seals essentially prevent inleakage of air and thus reoxidation. A number of fans are installed on the shell of the kiln; these supply the necessary process air via so called air tubes or via air injection nozzles in the feed zone of the rotary kiln. The charge passes through the kiln in ca. 8-12 h.

For more information please contact us.