Sintering

Very fine material is undesirable in the reduction equipment. The blast furnace is the dominant type of equipment for the production of iron metal. The principle of sintering involves the heating of iron ore fines along with flux and coke fines or coal to produce a semi-molten mass that solidifies into porous pieces of sinter with the size and strength characteristics necessary for feeding into the blast furnace. It is basically an agglomeration process. Sinter consists of a calcium ferrite matrix, with siliceous and aluminous constituents dissolved and primary hematite embedded in it (fig 1)

The Process

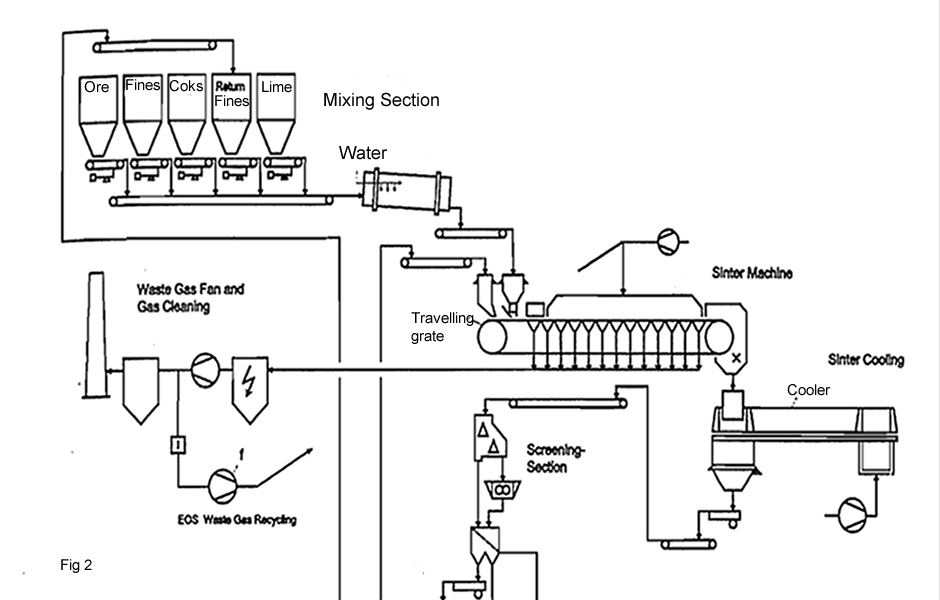

Iron ore sinter are virtually all produced in travelling-grate installations (fig 2).The process of sintering begins with the preparation of the raw materials consisting of iron ore fines, fluxes, in-plant metallurgical waste materials, fuel and return fines of the sinter plant. These materials are mixed in a rotating drum and water is added in order to reach proper agglomeration of the raw materials mix. This agglomeration is in the form of micro-pellets. These micro pallets assist in obtaining optimum permeability during the sintering process. These micro pellets are then conveyed to the sintering machine and charged.

A layer of controlled size sinter (bedding) is fed to the bottom of the sinter machine grates for the protection of the grates. After this the moistened micro pellets of the raw materials mix is fed and levelled.

After the material is leveled on the sinter machine, the surface of the charged material on the sinter machine is ignited using gas or oil burners. Air is drawn through the moving bed causing the fuel to burn. At the end of the machine the sintered material in the form of cake is discharged into the hot sinter crusher. Here the hot sinter cake is crushed to a pre-determined maximum particle size. From here the sinter is discharged onto sinter cooler which can be either straight line or circular cooler. After cooler the sinter is transferred to the screening section. The sinter products are tested for the following items:

- Chemical analysis

- Grain size distribution

- Reducibility

- Sinter strength

For more information please contact us.