Metal Matrix Composites

Metal Matrix Composites (MMCs) are composed of a metal matrix and a reinforcement, or filler material, which give excellent mechanical performance to the materials. The principal matrix materials for MMCs are aluminium and its alloys but there are several another nonferrous metals such as Mg, Ti, Cu, Zn and Pb. Continuous fibre reinforced MMCs are generally accepted as offering good mechanical properties and commercial potential.

The MMCs are new materials and lot of consumers are not aware of the variety of materials systems and their application such as carbides for machining of materials in product of engineering , noble metal composite systems for contacts in electronics and electro-technology, copper–graphite sliding contacts for generators and electric motors and multicompound systems for brake linings in high speed brakes.

Today high demand is for good electrical and thermal properties combined with high strength and wear resistance .For this purpose, it is interested only the composite materials.

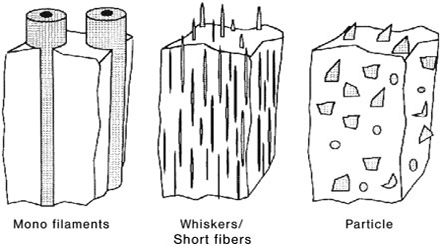

Metal matrix composites can be classified in various ways. One classification is the consideration of type and contribution of reinforcement components in particle-,layer-, fibre- and penetration composite materials .The composite microstructures may be subdivided, as show in figure1,according to whether the reinforcement is in the form of continues fibres, short fibres or particles .Table1 shows some important Metal Matrix Composites and their Properties.

Fig 1: Schematic depiction of the three types of MMS, classified to the type of reinforcement.

Table 1: some Metal Matrix Composites and their Properties.

| Material | Fiber content(%) | Density(g/cm) |

Tensile strength(MPa) | Young's modulus(GPa) |

| Monofilaments | ||||

| B/Al | 50 | 2.65 | 1500 | 210 |

| SiC/TiAl6V4 | 35 | 3.86 | 1750 | 300 |

| Multifilaments | ||||

| SiC/Al | 50 | 2.84 | 259 | 310 |

| Al2O3/Al–Li | 60 | 3.45 | 690 | 262 |

| C/Mg-Leg | 38 | 1.8 | 510 | |

| SiC/Al | Al+55–70% SiC | 2.94 | 226 | |

| MCX-736TM | MCX-736TM Al+55–70% SiC | 2.96 | 225 |