Abstracts of some Papers

Thermochemical preparation of W–25%Cu nanocomposite powder through a CVT mechanism

M. Hashempoura, H. Razavizadehb, H.R. Rezaieb, M.T. Salehib, M A T E R I A L S C H A R A C T E R I Z A T I O N 6 0 ( 2 0 0 9 ) 1 2 3 2 – 1 2 4 0

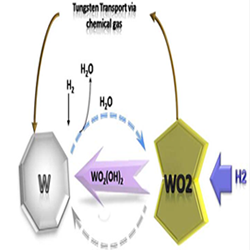

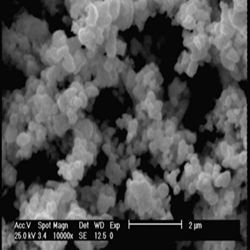

In order to produce aW–25%Cu nanocomposite powder manufactured by a thermochemical procedure a novel pair of precursors were used. Cu2WO4(OH)2 and CuWO4.2H2O precipitates were first produced by reacting the copper nitrate and sodium tungstate aqueous solutions under certain pH and temperature. The precipitates were then dried and calcined in order to prepare CuWO4 − x, CuO, and WO3 oxide powders for the next step reduction. The reduction was carried out under a H2 atmosphere to form the final W–Cu metal nanocomposite powder. Characteristics of the final powder such as distribution, uniformity and size were then discussed based thoroughly on the dominant mechanism of reduction; Chemical Vapor Transport. It was found that the average particle size of the reduced powder is 35 nm for W and 54 nm for Cu.

The publication is available at link:elsevier.com

Elsevier(Materials-Characterization)

An investigation about the activation energies of the reduction transitions of fine dispersed CuWO4-x/WO3-x oxide powders

M. Ardestani, H. Arabi, H. Razavizadeh, H.R. Rezaie, B. Jankovic, S. Mentus, Int. Journal of Refractory. 28 (2010) 383–387

Non-isothermal reduction of fine dispersed CuWO4-x/WO3-x oxide phases were investigated by thermogravimetry (TG) and differential thermogravimetry (DTG) analyses under hydrogen atmosphere and the activation energies of the corresponding reduction transitions determined by Kissinger–Akaira–Sunose (KAS) and Flynn–Wall–Ozawa (FWO) methods. The activation energy of the first reduction stage (CuWO4-x = Cu + WO3-x) using the mentioned methods were defined as EKAS(stepI)=34 kJ mol-1 and EFWO(stepI}= 41 kJ mol-1, respectively. Also, the ''E" values were determined as EKAS(stepII)=91.8kJ mol-1 and EFWO(stepII)=101kJ mol-1 for the second and EKAS(stepIII)=147.2kJ mol-1 and EFWO(stepIII) = 156.3kJ mol-1 for the third reduction steps (WO3-x= II WO2=III W), respectively. The results showed that copper from one side helps (WO2=W) reduction to start at lowered temperatures, but, from the other side, it enlarges the activation energy of this reaction by about 20 kJ mol-1. This increase explained by the fact that copper acts as a barrier for formation and transportation of volatile WO2(OH)2 compound which is the main agent responsible for reduction of tungsten oxide

The publication is available at link:elsevier.com

Elsevier(Int. Journal of Refractory metals and hard materials. )

A Process for Production of Titanium Aluminide: Reaction Mechanism

A. R. Kamali , H. Razavizadeh and S. M. M. Hadavi, International Journal of Self-Propagating High-Temperature Synthesis, 2007, Vol. 16, No. 3, pp. 119–124

A new combustion synthesis process for production of TiAl from TiO2 , Al, Ca and KClO4 has been developed. In a closed reaction vessel, this process gets started at about 505 °C with the reaction between Ca and KClO4 yielding CaO and KCl. Subsequent two-stage reaction between TiO2 and Al leads to formation of titanium aluminides and α-Al2O3. Then the reaction between α-A2O3and CaO results in formation of CaAl4O7(grossite). The overall reaction scheme can be represented as:

6TiO2+ 22Al + 4KClO4+ 4Ca = 6TiAl +4CaAl4O7+ 4KCl

The temperature reached in the process (1950 °C) is high enough for the melting of TiAl and CaAl4O7 and evaporation of KCl.

Key words: TiAl, combustion synthesis, KRH process, DTA, ignition temperature

The publication is available at link:Springer .com

Springer(Journal of Self-Propagating High-Temperature Synthesis)

Investigation on wear mechanism of thermochemically fabricated W–Cu composites

M. Hashempour∗, H. Razavizadeh, H. Rezaie, Wear 269 (2010) 405–415

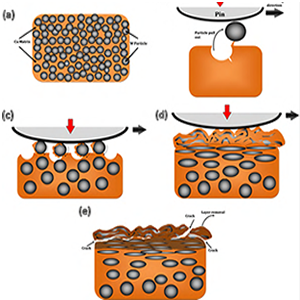

W–25wt%Cu nanocomposite powder was prepared by thermochemical co-precipitation method. Consolidation procedure was performed at 1200 oC under hydrogen atmosphere and led to the densification up to 98% theoretical density. Wear test was carried out with a pin-on-disc apparatus under 5, 10, and 15N normal loads. Volume of the lost material and also the wear rate increased by increasing the normal load while, friction coefficient showed a reverse record and decreased by increasing the load. Formation of mechanically mixed layers (MMLs) and their successive deformation and work hardening was found to be the origin of the friction coefficient decrease at increased normal loads. At low normal load just shallow scuffs and particle pull out were observed in the surface and sub-surface studies of the wear sample.But at higher normal loads large flakes of the matter were cut off and lost accompanying deep grooves and branched cracks. Continuous cyclic deformation at sufficiently high normal loads, could give rise to MML formation, sub-surface deformation, crack nucleation and propagation, and finally delamination of the composite.

The publication is available at link:elsevier.com

Effect of electroplating parameters on properties of Zn–nano-TiO2 composite coatings

T. Mokabber, S. Rastegari and H. Razavizadeh, Surface Engineering 2013 VOL 29 No1

In this paper, Zn–nano-TiO2 composite coatings were deposited on the mild steel substrate. Coatings were produced by electroplating method from sulphate bath in which nanosized TiO2 particles were suspended. The chemical composition and surface morphology of coatings were investigated using energy dispersive spectroscopy and scanning electron microscopy respectively. Corrosion behaviour of the coatings was studied in 3.5 wt-% NaCl solutions, and their microhardness was evaluated through Vickers microhardness test. According to the results, the parameters of current density, particle concentration in the solution and temperature were optimised with respect to TiO2 content in the composite coatings. The optimised current density, particle concentration and temperature of the bath were found to be 3 A dm-2, 5 g L-1 and 40 oC respectively. Accordingly, an increase in the amount of TiO2 particles in the composite coatings increases the hardness of composite coatings but did not have harmful effects on corrosion resistance.

Keywords: Composite, Coating, Electroplating, Zn–TiO2, Corrosion, Microhardness

The publication is available at link:maneyonline.com

Maneyonline(Surface Engineering)

Synthesis and consolidation of W–Cu composite powders with silver addition

G. Taghavi Pourian Azar, H.R. Rezaie, H. Razavizadeh, International Journal of Refractory Metals and Hard Materials, Volume 31, March 2012, Pages 157-163

Homogeneous and nanostructured W–19 wt.%Cu–1 wt.%Ag and W–10 wt.%Cu–10 wt.%Ag composite powders were prepared via a chemical precipitation method, with the aim of surveying the effect of silver on the properties of tungsten–copper composites. For this purpose, ammonium metatungstate, copper nitrate and silver nitrate with predetermined weight proportion were separately dissolved in distilled water. Furthermore, W–20 wt.%Cu composite powders were provided for comparison. The initial precipitates were obtained by reacting a mixture of the mentioned solutions under certain pH and temperature. The precursor precipitates were then washed, dried, and calcined in air to form oxide powders. In the next step, the reduction was carried out in hydrogen atmosphere to convert them into the final nanocomposite powders. The resulting powders were evaluated using X-ray diffraction (XRD), thermogravimetry (TG) and scanning electron microscopy (SEM) techniques. The effect of sintering temperature was investigated on densification and hardness of the powders compacts. The results showed that at all sintering temperatures, by increasing in the amount of silver, powders showed better sinterability compared to W–20 wt.%Cu powders. Maximum relative densities of 97.7%, 98.2% and 99.6% were achieved for W–20 wt.%Cu, W–19 wt.%Cu–1 wt.%Ag and W–10 wt.%Cu–10 wt.%Ag compacts sintered at 1200 °C, respectively. Moreover, maximum hardness of 359, 349 and 255 Vickers were resulted for W–20 wt.%Cu, W–19 wt.%Cu–1 wt.%Ag and W–10 wt.%Cu–10 wt.%Ag compacts sintered at 1200 °C, respectively.

The publication is available at link: , International Journal of Refractory Metals and Hard Materials.com,

International Journal of Refractory Metals and Hard Materials

Application and conceptual explanation of an energy-based approach for the modelling and prediction of sliding wear

M. Jahangiri, M. Hashempour, H. Razavizadeh, H.R. Rezaie, Wear, Volumes 274–275, 27 January 2012, Pages 168-174

Establishing an accurate predictive model for wear will result in major improvements in the efficiency, lifetime, cost and performance of many engineering systems. The authors have previously proposed a practical energy-based model to describe the tribological damage using energy dissipation. In this work, the capacity of this method to simplify the complex wear phenomenon was determined, and the applicability of this method to forecast the wear behaviour of materials was investigated. The wear results for a W–Cu electrical contact composite were utilised to determine the practical value of the model. Numerical integration of friction force–distance diagrams was used to evaluate the energy dissipation. Linear and non-linear least squares methods were applied to find the optimal curve fitting. It is shown that this model can be applied in two general forms: (1) a graphical method and (2) an explicit formulation. Both of these forms are shown to be capable of providing the necessary information, based on a limited number of initial tests, to predict unknown wear data (volume loss, lifetime, energy) without the need for morphological observations.

The publication is available at link:elsevier.com

A new method to investigate the sliding wear behaviour of materials based on energy dissipation: W–25 wt%Cu composite

M. Jahangiri, M. Hashempour, H. Razavizadeh, H.R. Rezaie, Wear, Volumes 274–275, 27 January 2012, Pages 175-182

A new method is proposed to explain and monitor wear behaviour based on energy dissipation. The wear of a W–25 wt%Cu composite against 52100 steel was used to demonstrate this approach with pin-on-disc tests conducted under three normal loads. An energy-dependent criterion, namely, specific wear volume (wear volume/dissipated energy (mm3/J)), was defined to evaluate the wear of the composite. The specific wear volume can be used as a substitute for the traditional wear rate due to the simultaneous expression of several wear parameters and because of its strong dependence on the wear mode. The specific wear volume appears to be constant in any particular "wear mode" regardless of the active "wear processes". In the wear of this composite, processes such as particle pull-out, mechanically mixed layer (MML) formation, crack propagation and delamination were observed. But, combination of these processes in each test had identical specific wear volumes. Thus, all of these wear processes were considered to be consecutive stages of the same wear mode: fatigue wear. The amount of dissipated energy and the volumetric loss increased with increasing normal load. Also, changing the normal load changed the rate of energy dissipation per unit sliding distance.

The publication is available at link:elsevier.com

EFFECTS OF PRECURSOR ROOTED CONTAMINATION IN THE SINTERING AND DENSIFICATION BEHAVIOR OF THERMO-CHEMICALLY MANUFACTURED W-CU NANOCOMPOSITES

MAZDAK HASHEMPOUR,HEKMAT RAZAVIZADEH,HAMID REZA REZAIE, International Journal of Modern Physics B,Vol. 24, No. 1 & 2 (2010) 183–190

Tungsten and copper, two metals of complete mutual immiscibility, show a variety of densification behaviours due to the processing condition in the sintering stage. In this regard, the presence of different impurities during the densification process, have different influences on the consolidation of the primary powder. In this work, the effects of impurities introduced to the powder by the precursor salt in a novel thermo-chemical homogeneous co-precipitation method were investigated. Addition of sodium tungstate to the aqueous solution of copper nitrate saturated in aqueous ammonia solution, will result in precipitation of CuWO4.2H2O which will float in a mass of wandering Na+ ions in the solution. Removal of these sticking ions by multi stage washing has a certain effect on the final density of the sintered powder. The density of the sintered product was evaluated both with and without the removal of the Na and the mechanism by which this impurity deteriorates the densification was discussed in this work.

Keywords: W-Cu Nanocomposite; Contamination; Sintering

The publication is available at link:International Journal of Modern Physics B.com

International Journal of Modern Physics B

PREPARATION AND SINTERING OF W-20%Wt Cu COMPOSITE POWDERS PRODUCED BY CO-PRECIPITATION METHOD

M. Ardestani, H. Razavizadeh, H. Arabi and H. R. Rezaie, Iranian Journal of Materials Science & Engineering Vol. 6, Number 2, Spring 2009

W-Cu composites are widely used as contacts, heat sinks and electro discharge electrodes. These kinds of materials can be fabricated by sintering of W-Cu composite powders. In this research W-20%wt Cu composite powders was synthesized via a co-precipitation method. Precipitate obtained from a mixture of copper nitrate and ammonium paratungstate (APT) in distilled water contained W-Cu compounds. This precipitate was washed, dried and calcined at 550 °C in air and then reduced in H2 atmosphere in order to convert to W-Cu powders. The calcination temperature of dried precipitate powder was determined by thermogravimetry (TG), differential thermal analysis (DTA) and X-ray diffraction (XRD). The sintering of the reduced powders was investigated as a function of temperature. Relative density of more than 98% obtained for the powders sintered at 1200°C . The corresponding electrical conductivity was too close to theoretical calculations. The hardness of the sintered powders was 320 Vickers.

Keywords: W-Cu composites; Co-precipitation; Thermal analysis.

The publication is available at link: Iranian Journal of Materials science and Engineering.com ,

Iranian Journal of Materials science and Engineering

Synthesis and densification of W–30 wt%Cu composite powders using ammonium meta tungstate and copper nitrate as precursors

M. Ardestani , H. Arabi, H.R. Rezaie, H. Razavizade Int. Journal of Refractory Metals & Hard Materials 27 (2009) 796–800

W–30 wt%Cu composite powders were prepared by a novel precipitation process using ammonium meta tungstate and copper nitrate as precursors. The initial precipitates were obtained by adding aqueous ammonia to a mixture of ammonium meta tungstate and copper nitrate solutions and then heating the solution up to 95 oC. In order to synthesis W–Cu composite powders, the dried precipitates were calcined in air at 500 oC and then reduced by hydrogen. The calcination temperature was determined by thermogravimetry analysis. The powders were characterized by X-ray diffraction technique and scanning electron microscopy analysis. The effect of sintering temperature was investigated on densification of the synthesized powders. Relative density over 98% was achieved for the samples which were sintered at 1150 oC. Good electrical conductivity and relatively high hardness were achieved for the samples which sintered above melting point of copper.

Keywords: W–Cu composites, Precipitation, Calcination, Sintering

The publication is available at link: , International Journal of Refractory Metals and Hard Materials.com,

International Journal of Refractory Metals and Hard Materials

Microstructure Refining of a Cast TiAl alloy via Homogenizing and Post Heat-Treatment Processes

Siavash Zamani ,Hekmat Razavizadeh ,Mohammad Jahazi ,NAMIC 2012 - May 30-31

In the present study, the homogenizing and post heat-treatment processes were employed to refine the as-cast microstructure of a TiAl alloy.

In order to this reason, microstructure evolution, phase consistence and hardness of the alloy were characterized and studied using optical and scanning electron microscopies and Vickers micro-hardness measurements. The nominal composition of the cast alloy was Ti- Al- Cr at.% which produced using the vacuum arc re-melting (VAR) process. Initial microstructure of the cast ingot was a large size columnar structure and different post heat-treatment routs were designed so that the final structure was a fine duplex (DP) microstructure. Homogenizing process was performed at °C for hours in the controlled atmosphere. Also, in order to find the optimized heat-treatment cycle, the effects of variations of heating rate in range of ° C/min to °C/sec, solution temperature in range of to °C, solution time in range of to min and cooling rate in range of °C/min to water quench condition, on the characteristics of the microstructure evolution and different phases present in the structure were studied. Analysis of the results indicated that, a combination of heating and cooling rates increasing and selection of optimum solution temperature leads to achieve a fine duplex microstructure.

Keywords : TiAl, heat treatment, microstructure, refining, hardness

The publication is available at link:NAMIC 2012.pdf

The Effects of Chromium Addition on the Mechanical Properties of a Binary TiAl Alloy at Elevated Temperatures

Siavash Zamani ,Hekmat Razavizadeh ,Mohammad Jahazi, NAMIC 2012 - May 30-31

In the present study, the influence of chromium addition on the mechanical behavior of a binary TiAl at elevated temperatures was studied. The compositions of the binary and ternary alloys was Ti- Al and Ti- Al- Cr at.% prepared and cast using vacuum are remelting (VAR) process. Homogenizing and a post heat-treatment processes were employed and performed on the cast ingots to refine the microstructure of the samples to a refined duplex (DP) structure. Tension test at elevated temperatures was selected as a representative for the mechanical behavior of the alloys. Tensile yield and ultimate strengths and elongation of the samples were tested and measured at ambient temperature, , , , , and °C. In the other hand, optical and scanning electron microscopies followed by energy dispersive X-ray spectroscopy (EDS) and image analyses were used to characterize the microstructure of the samples. It was found that Cr addition to about at.% can increase both the strength and ductility of TiAl in ambient and elevated temperatures. The yield strength and elongation of the binary alloy were improved for about % and % respectively at ambient temperature and % and % at °C. The ultimate strength of both alloys was increased about and % for binary and ternary alloys in temperature range of - °C. Moreover, it was cleared that chromium can perform such effects by changing in both the microstructural and interstitial features of binary TiAl. The effects of Cr on the strength and ductility of the alloy were intensified drastically above °C which showed the thermally activated nature of the performed changes

Keywords : Titanium Aluminide, Chromium, Mechanical Properties, Alloying Design

The publication is available at link:NAMIC 2012.pdf

TITANIUM ALUMINIDES SYNTHESIS BY ALUMINO-CALCIOTHERMIC REDUCTION OF TiO2

A. R. Kamali, S. M. M. Hadavi, H. Razavizadeh, J. Fahim, Iranian Journal of Materials Science & Engineering Volume 5, Number 2 (6-2008)

Production of titanium aluminides in TiO2-Al-Ca system has been investigated. For this purpose, different compositions of raw materials were studied in a special reaction vessel. In a special case, the non-completed reaction of TiO2with Al and Ca resulted in the production of granulates of titanium aluminides especially Ti3Al and other Ti – Al phases as the metallic product an Ca12Al14O33 as the non-metallic product. Remelting of metallic granulates led to production of TiAl ingot.

Keywords: Titanium Aluminide, Titanium Dioxide, Alumino-Calciothermic.

The publication is available at link: Iranian Journal of Materials science and Engineering.com ,

Iranian Journal of Materials science and Engineering

Einfluss der Kalziumhexaborid(CaB6)-Desoxidation auf elektrische Kennwerte vor Kupfer

Kh.G. Schmitt-thomas,H.Meisel,H-J.Dorn und H.Rasavisadeh,Metall,12.29(1975)Seite1198-1204

In einer vergleichenden Untersuchung wird der Einfluss der Kupfer-desoxidation durch CaB6,P und Li auf die elektrische Leitfaehigkeit ermittlet. Es wird festgestellt,dass mit CaB6 eine wirkungsvolle desoxidation moeglich und im Gegensatz zur Desoxidation duch P und Li keine Leitfaehigkeitsabnahme zu erwarten ist.The influence ofcopper-deoidation by CaB6,P and Li on the electric conductivity is found out in a comparable test.

It is determined that an effective deoxidation with CaB6 is possible and in opposition by P and Li there is not to expect a decrease of electric conductivity.