Aluminium

Pure aluminium has the highest electrical conductivity at ambient temperature but has a very low yield strength of about 7 MPa, therefore its alloy will be more used in the industries. Aluminium alloys are used in engineering design chiefly for their light weight, high strength-to-weight ratio, corrosion resistance, and relatively low cost. They are also utilized for their high electrical and thermal conductivities, ease of fabrication, and ready availability. (Aluminium is the most widely distributed of the elements, except for oxygen, nitrogen, and silicon.

Physical Properties of Aluminium

| PROPERTY | VALUE | UNITS | PROPERTY | VALUE | UNITS |

| Atomic number | 13 | - | Atomic weight | 26.98 | - |

| Crystal structure | Fcc | - | Atomic radius | 1.18 | Ao |

| Density | 2.70 | g/cm3 | Melting point | 660.2 | oC |

| Boiling Point | 2470 | °C | Latent Heat of Fusion | 397.0 | kJ/kg |

| Thermal Conductivity at temperture 0-1000C | 244 | W/mK | Electrical Resistivity at 20 oC | 2.69 | μΩ·cm |

| Electrical Conductivity at 20 oC | 64.94 | %IACS | Modulus of Elasticity at 20 oC | 68.3 | GPa |

Classes of aluminium and aluminium alloy

3. Types Aluminium are available in various compositions, including "pure" metal, alloys for casting, and alloys for the manufacture of wrought products. (Alloys for casting are normally different from those used for rolling, forging, and other working.) All types are produced in a wide variety of industrial shapes and forms. Casting alloys, wrought alloys are produced in both heat-treatable and non-heattreatable types as following:

Pure Aluminium

Pure aluminium is available both as a high-purity metal and as a commercially pure metal. Both have relatively low strength, and thus have limited utility in engineering design, except for applications where good electrical conductivity, ease of fabrication, or high resistance to corrosion is important. Pure aluminium is not heat treatable. However, its mechanical properties may be varied by strainhardening (cold work). Pure aluminium exhibits poor casting qualities; it is employed chiefly inwrought form. Commercially pure aluminium is available as foil, sheet and plate, wire, bar, rod, tube, and as extrusions and forgings.Casting Alloys

The aluminium alloys for casting purposes contain one or more alloying elements, the maximum of any one element is not more than 12 %. Some alloys are designed for use in the as-cast condition; others are designed to be heat treated to improve their mechanical properties and dimensional stability. High strength, together with good ductility is obtained by selection of suitable composition and heat treatment. Aluminium Alloy Designation System (CEN) for Casting Alloys is as following:

| Nr | Alloying element | Nr | Alloying element |

| 1XXX0 | None (min. 99.00% Al) | 2XXX0 | Cu |

| 4XXX0 | Si | 5XXX0 | Mg |

| 7XXX0 | Zn | 8XXX0 | Sn |

| 9XXX0 | Master Alloys | - | - |

Wrought Alloys

Most aluminum alloys are used for wrought products contain Iess than 7 percent of alloying elements. The properties of the aluminium are enhanced and their working characteristics improved, by adding different of the amount and type of elements Special compositions have been developed for particular fabrication processes such as forging and extrusion. The mechanical properties of non-heat-treatable" type can be varied by strainhardening, or by strain-hardening followed by partial annealing. The mechanical properties of the heat-treatable types are improved by quenching from a suitable temperature and then aging. With the heat-treatable alloys, especially desirable properties may be obtained by a combination of heat treatment and strain hardening. The principal wrought forms of aluminium alloys are plate and sheet, foil, extruded shapes, tube, bar, rod, wire and forgings. Aluminium Alloy Designation System (CEN) for Wrought Alloys are as following:

Non-heat treatable alloys

| Nr | Alloying element |

| 1XXX | None (min. 99.00% Al) |

| 3XXX | Mn |

| 4XXX | Si |

| 5XXX | Mg |

Heat treatable alloys

| Nr | Alloying element |

| 2XXX | Cu |

| 6XXX | Mg + Si |

| 7XXX | Zn |

| 8XXX | Other |

Unalloyed Aluminium (Pure Aluminium)

Properties

- Electrical Conductivity and Resistivity

- Mechanical Properties

The electrical conductivity of 99.99% pure aluminium at 20 0C is 64.94 of the International Annealed Copper Standard (IACS). Because of its low specific gravity, the mass electrical conductivity of pure aluminium is more than twice that of annealed copper and greater than that of any other metal. The resistivity at 20 0C is 2.69 Ω.cm. The electrical conductivity which is the reciprocal of resistivity, is one of the more sensitive properties of aluminium being affected by both, changes in composition and thermal treatment. The addition of other metals in aluminium alloys lowers the electrical conductivity of the aluminium therefore this must be offset against any additional benefits which may be gained, such as an increase in strength. Heat treatment also affects the conductivity since elements in solid solution produce greater resistance than undissolved constituents. The very good electrical properties of aluminium have made it an obvious choice for applications in the electrical industry, particularly in power distribution where it is used almost exclusively for overhead transmission lines and busbars.

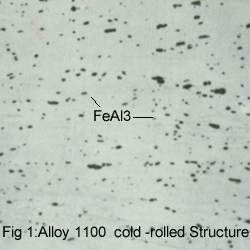

The tensile strength of annealed 99.99 % of super-purity(SP) aluminium is about 44..81 Mpa, with a yield strength of 10.34 Mpa and a elongation of 50 %.This aluminium is used in special application. As the impurity level is increased, the strength of aluminium increases a maximum in the 1000 series with 1100 alloy. The commercial-purity (CP) aluminium has 99% Al and up to 1% impurities or minor additions. The insoluble constituent in commercially pure aluminium are chiefly Fe and Si type as intermetallic such as FeAl3 or Fe3SiAl12 shown in figure1.The low tensile strength is 90 Mpa and Yield strength of 7-11Mpa in CP 1100.The applications of this aluminium are such as electrical conductors ,chemical process equipment,foils and decorative finishes.

Aluminium Alloys

Aluminium –Manganese Alloys

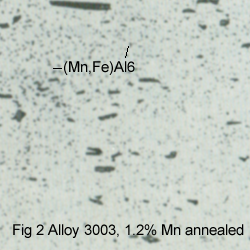

The addition of about 1.2% Mn to commercial purity aluminium (0. 6% Fe and 0.2% Si) produces a moderately strong non-heat –treatable aluminium alloy. The manganese addition strengthens the aluminium by solid –solution strengthening and by fine dispersion of precipitates. Still further increases in strength are possible by Mg addition up to about 1%.These alloys are used for general purposes where moderate strength and good workability such as Sheet metal work, storage tanks and pressure vessels are required. Figure 2 shows the microstructure of alloy 3003 sheet with 1.2 %Mn. This alloy is homogenized at about 600 0C, after it is cold-worked, annealed at 340 0C a fine dispersoid of ( Mn, Fe)Al6 and α (Al-Fe-Mn-Si constituents is formed. The tensile strength of this alloy is about 110 Mpa and its yield strength is about 41 Mpa.

Aluminium –Magnesium alloys

The magnesium in the commercial alloys ranges all the way from 0.5 to 12-13% Mg, the low-magnesium alloys having the best formability, the high-magnesium reasonably good castability and high strength. It is normal practice to prepare these alloys from the higher grades of aluminium (99.7 or better) to obtain maximum corrosion resistance and reflectivity; thus the iron and silicon contents are usually lower than in other aluminium alloys.

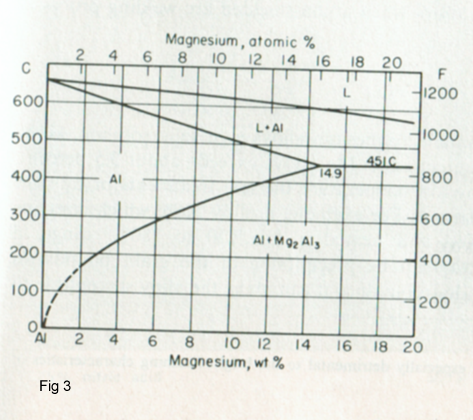

Figure 3 shows the binary diagram of Al-Mg alloys, which are the basis for the 5000 series of non-heat-treatable aluminium alloys. Mg has a substantial solid solubility in aluminium at 451 0C 14.9% and greatly decreasing solid solubility with decreasing temperature. Aluminium-magnesium alloys do not show appreciable precipitation hardening at concentrations less than 7% Mg .Magnesium does, however ,substantially strengthen aluminium by solid solution strengthening and it cases high work-hardening characteristics.

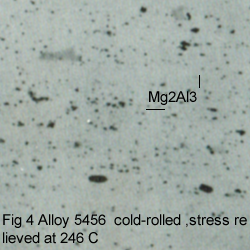

The Magnesium in most Al Mg alloy is in solid solution. However, when the magnesium content is more than 3.5 %Mg , Mg2Al3 can be precipitated by low temperature(fig 4). For example Mg additions (08-5%) provide solid solutions and give a wide range of alloy compositions in Al-Mg alloys (5000 series)The strength properties are as following:

| Nr | yield strength(MPa) | tensile strength(MPa) |

| Al-0.8Mg (5005) | 40 | 125 |

| Al-(4.7-5.5(5456) | 160 | 310 |

These alloys have high rate of work hardening, corrosion resistance and bright surface finishing and is used in Transportation structural plates, Large tanks for petrol, milk, grain ,Pressure vessel and architectural components.

For more information please contact us.