Casting

Casting involves pouring liquid metal into a mold, which has a hollow cavity of the desired shape, and then allowing it to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years.

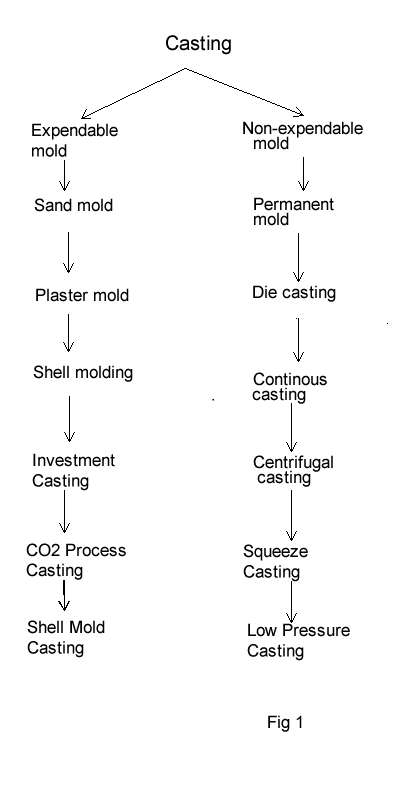

The modern casting process is divided into two main categories as following (fig 1):

- Expendable casting

- Non-expendable casting

It can further broken down by the mold material, such as sand or metal, and pouring method, such as gravity, vacuum, or low pressure.

Expendable casting

Expendable casting uses sand, plastic, shell, plaster, and investment (lost-wax technique) moldings , clay or metal molds for the casting process. These molds are discarded after use. This method of mold casting involves the use of temporary, non-reusable molds such as Sand casting, Plaster mold casting and Shell molding

Non-expendable mold

Non-expendable mold casting uses molds that are intended for permanent use over long runs. The molds are generally metal, but the method of performing the casting differs greatly from many expendable methods. It differs from expendable processes in that the mold need not be reformed after each production cycle. This technique includes at least four different methods: permanent, die, centrifugal, and continuous casting. This form of casting also results in improved repeatability in parts produced and delivers Near Net Shape results.