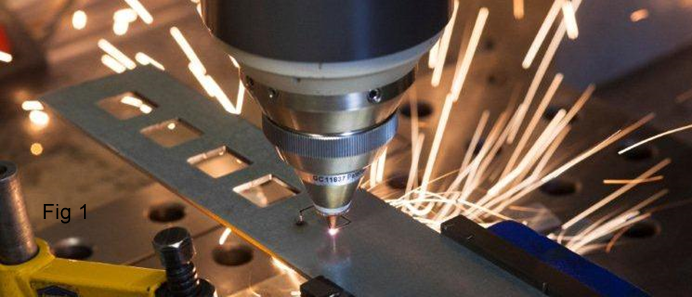

Laser Beam Machining (LBM)

Laser beam machining is a non-traditional subtractive manufacturing process, a form of machining, in which a laser is directed towards the work piece for machining. This process uses thermal energy to remove material from metallic or nonmetallic surfaces (fig1). Laser represents the full form of Light Amplification by Stimulated Emission of Radiation. It means, the laser beam focuses optical energy on the surface of the workpiece. A laser beam is so powerful when is used with lens system that it can melt and vaporize diamond as the energy density of about 105 kW/cm2. This huge amount of energy is released due to some specific atoms having higher energy levels and particular frequency. The laser is focused onto the surface to be worked and the thermal energy of the laser is transferred to the surface, heating and melting or vaporizing the material. Laser beam machining is best suited for brittle materials with low conductivity, but can be used on most materials.

Types of Lasers

There are many different types of lasers such as gas, solid states lasers, and excimer:

- Gas Laser

- Solid state

- Ruby-laser

- Excimer lasers

A gas laser is a laser in which an electric current is discharged through a gas to produce coherent light. The gas laser was the first continuous-light laser and the first laser to operate on the principle of converting electrical energy to a laser light output.Some of the most commonly used gases consist of; He-Ne, Ar, and CO2.

Solid state lasers are designed by doping a rare element into various host materials. Solid state lasers are pumped optically by flash lamps or arch lamps. Solid state lasers are either semiconductor (or diode) lasers pumped electrically or those with a crystalline or glass matrix pumped optically.

Ruby is one of the frequently used host materials in this type of laser. A Ruby Laser is a type of the solid state laser whose laser medium is a synthetic ruby crystal. These ruby lasers generate deep red light pulses of a millisecond pulse length and a wavelength of about 694.3 nm. The synthetic ruby rod is optically pumped using a xenon flashtube before it is used as an active laser medium. Ruby-laser or crystalline aluminium oxide or saphire is the most commonly used solid state laser. Generally these lasers are fabricated in into rods having length about 150 mm. Their ends are well furnished to close optical tolerances.

In excimer lasers, the state is different than in solid state or gas lasers. The device utilizes a combination of reactive and inert gases to produce a beam. This machine is sometimes known as an ultraviolet chemical laser.It is a form of ultraviolet laser which is commonly used in the production of microelectronic devices, semiconductor based integrated circuits or "chips", eye surgery, and micromachining.

Some advantages and disadvantages are as following:

Advantages

- Micro sized holes can created in all types of materials.

- Even very tiny holes can be produced

- Machining is extremely rapid

- There is any direct contact between tool and workpiece, therefore No tool wear is necessary.

- Operating process cost is very low

Disadvantages

- The equipment cost is very high.

- Lifespan of the flash lamp is short.

- Too deep holes are not possible to drill.

- Tapers are normally encountered in direct drilling of holes.

- The thickness of material which has to be laser drilled is restricted to 50mm.

Some Applications

- Cutting of materials, both soft and hard materials

- Welding of non-conductive and refractory material

- For producing fine and minute holes

- Scribing of any material

- Drilling of all substrates

- Trimming all the hybrid resistors