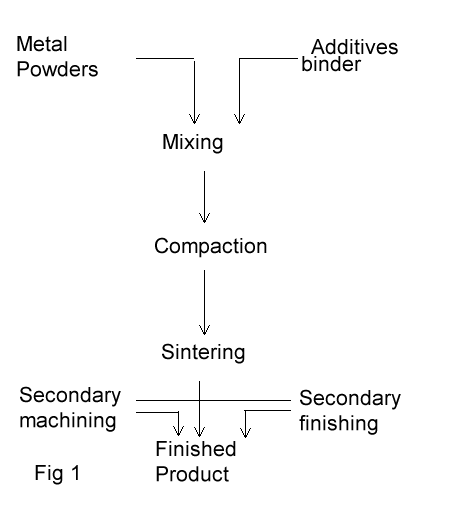

Conventional Powder Metallurgy Process

Powder metallurgy is the production and working of metals as fine powders which can be pressed and sintered to form objects. Figure 1 shows schematically the process production , consists of mixing elemental or alloy powders, compacting the mixture in a die, and then sintering, or heating, the resultant shapes in an atmosphere-controlled furnace to bond the particles metallurgically.

Various powder metals such as stainless steel, brass, copper, iron and bronze are compressed and then sintered (heated) to metallurgically bond the particles. Material blending allows for a certain amount of customization of material properties to produce desired characteristics suitable for a particular application.

Powder Metallurgy comprises a family of production technologies, which process a feedstock in powder form to manufacture components of various types. These production technologies generally involve all or most of the following process steps:

- Powder production

- Mixing of powders

- Forming of the mixed powder into a compact

- Sintering of the compact to enhance integrity and strength.

- Secondary operations

Any fusible material can be atomized. Several techniques have been developed which permit large production rates of powdered particles, often with considerable control over the size ranges of the final grain population. Powders may be prepared by crushing, grinding, chemical reactions, or electrolytic deposition.

This can often involve the introduction of alloying additions in elemental powder form or the incorporation of a pressing lubricant.

The dominant consolidation process involves pressing in a rigid toolset, comprising a die, punches and, possibly, mandrels or core rods. However, there are several other consolidation processes that are used in niche applications.

This process step involves heating of the material, usually in a protective atmosphere, to a temperature that is below the melting point of the major constituent. In some cases, a minor constituent can form a liquid phase at sintering temperature; such cases are described as liquid phase sintering.

The application of finishing processes to the sintered part. In the Powder Metallurgy industry, such processes are often referred to as "secondary operations".