Gas tungsten arc welding (GTAW)

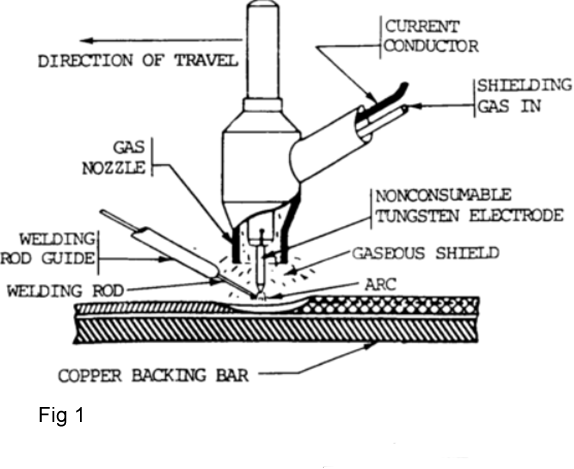

Gas tungsten arc welding (GTAW) also known as TIG (tungsten, inert gas), uses a non-consumable tungsten electrode to produce the weld. and the work to be welded. The weld is shielded from the atmosphere by a shielding gas that forms an cover, around the weld area. The GTAW process is versatile and can be used on ferrous and nonferrous metals. An arc is produced between a nonconsumable electrode and the work to be welded (fig1).

When welding thinner materials, edge joints, and flange, filler metals are not used. For thicker materials, an externally fed filler wire is generally used. The type of filler metal wire to be used is based on the chemical analysis of the base metal. The size of the filler metal wire depends on the thickness of the base metal, which usually dictates the welding current.

Gas tungsten arc welding produces exceptionally clean welds no slag is produced, the chance inclusions in the weld metal is and the finished weld requires virtually no cleaning. Argon and Helium, the primary shielding gases employed, are inert gases. Inert gases do not chemically combine with other elements and therefore, are used to exclude the reactive gases, such as oxygen and nitrogen, from forming compounds that could be detrimental to the weld metal.

Gas tungsten arc welding may be used for welding almost all metals — mild steel,low alloys, stainless steel, copper and copper alloys, aluminum and aluminum alloys, nickeland nickel alloys, magnesium and magnesium alloys, titanium, and others. This process is most extensively used for welding aluminum and stainless steel alloys another use is for the root pass (initial pass) in pipe welding, which requires a weld of the highest quality. For high quality welds, it is usually necessary to provide an inert shielding gas inside the pipe to prevent oxidation of the inside weld bead.

Pure tungsten is used on nonferrous metals, such as aluminum and magnesium. Thoriated tungsten is the most common type of tungsten electrode for use on carbon and stainless steel. For quite some time, tungsten manufacturers have added an oxide to pure tungsten to improve the arc starting characteristics and the longevity of welding electrodes. While 2% thoriated tungsten has been the most commonly used tungsten material Zirconiated tungsten is typically used for welding with higher AC currents on nonferrous metals.