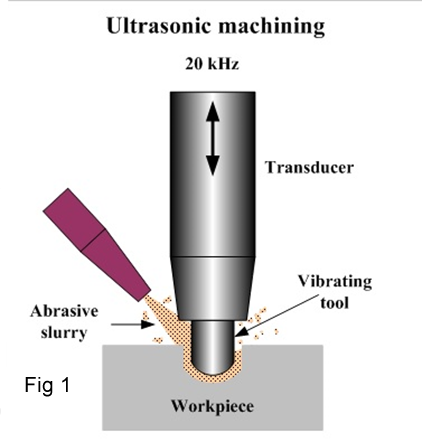

Ultrasonic machining (USM)

Ultrasonic machining is a subtraction manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles (fig 1). It means, it is a non-traditional process, in which abrasives contained in slurry are driven against the work by a tool oscillating at low amplitude (25-100 microns) and high frequency (15-30 kHz).

In ultrasonic machining, tool of desired shape vibrates at ultrasonic frequency ( 19 to 25 kHz. ) with an amplitude of 15-50 Microns over work piece. Generally tool is pressed down with a feed force F. Between the tool and work, machining zone is flooded with hard abrasive particles generally in the form of water based slurry. As the tool vibrates over the work piece, abrasive particles acts as indenter and indent both work and tool material. Abrasive particles , as they indent , the work material would remove the material from both tool and work piece. In Ultrasonic machining material removal is due to crack initiation, propagation and brittle fracture of material. USM is used for machining hard and brittle materials, which are poor conductors of electricity and thus cannot be processed by Electrochemical machining ( ECM) or Electro discharge machining (EDM).

The tool in USM is made to vibrate with high frequency on to the work surface in the midst of the flowing slurry. The main reason for using ultrasonic frequency is to provide better performance. Audible frequencies of required intensities would be heard as extremely loud sound and would cause fatigue and even permanent damage to the auditory apparatus. Tools vibrate at high-frequency (19-25kHz) and very-low amplitudes (few thousandths of an inch). This mobilizes the abrasive-liquid slurry between the tool and the workpiece and removes material by erosion. This produces shapes and cavities that traditional methods cannot.