Gas metal arc welding (GMAW)

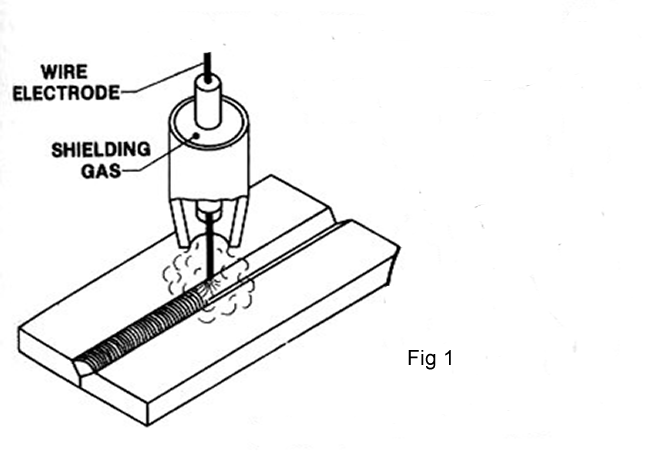

Gas metal arc welding (GMAW): commonly termed MIG (metal, inert gas), uses a wire feeding gun that feeds wire at an adjustable speed and flows an argon-based shielding gas or a mix of argon and carbon dioxide (CO2) over the weld puddle to protect it from atmospheric contamination (fig1), it is a welding process which joins metals by heating the metals to their melting point with an electric arc. The arc is between a continuous, consumable electrode wire and the metal being welded. The GMAW process is suitable for fusing mild steel, stainless-steel as well as aluminium.

GMAW provides a considerable increase in weld metal deposition rates compared to GTAW or SMAW, and when implemented as a semi-automatic process, less welder skill is typically required. However, GMAW equipment is more complex, less portable, and generally requires more routine maintenance than for the GTAW and SMAW processes. GMAW is the most common process for welding corrosion-resistant alloys and for performing thick-section welds.

A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used. There are four primary methods of metal transfer in GMAW, called globular, short-circuiting, spray, and pulsed-spray, each of which has distinct properties and corresponding advantages and limitations.