Electrochemical machining (ECM)

Electrochemical machining is a method of removing metal by an electrochemical process. It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods. Its use is limited to electrically conductive materials. It is a non-traditional machining process uses principle of Faraday Low to remove metal from the work piece.

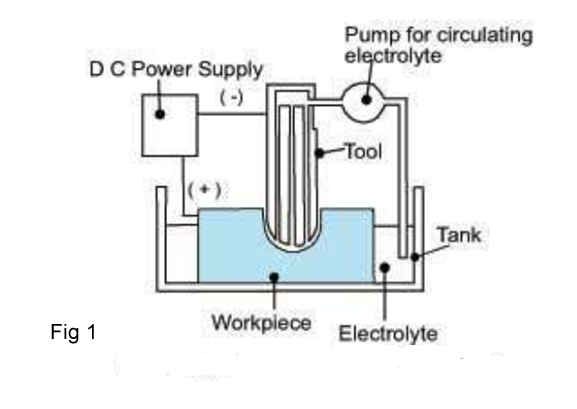

During the ECM process metal is dissolved from a workpiece with direct current at a controlled rate in an electrolytic cell. The workpiece serves as the anode and is separated by a gap (which can be as small as 10 µm) from the tool, which serves as the cathode. Therefore, the work piece and the work tool do not touch in any moment. The electrolyte, usually a salt solution in water, is pumped under pressure through the inter-electrode gap, thus flushing away metal dissolved from the workpiece. As the electrode tool moves towards the work piece to maintain a constant gap, the workpiece is machined into the complementary shape of the tool (fig 1).

Electrochemical Machining is performed by reversing the process of electroplating; ECM utilizes the principle of electrolysis for metal removal. High rate of electrolyte movement in the tool-workpiece gap washes metal ions away by anodic dissolution from the electrically conductive workpiece. Material removal rate (m) is an important characteristic in evaluating the efficiency of the non-traditional machining processes. In ECM, material removal takes place due to the atomic dissolution of the work material.

ECM Metal Removal Rate is independent of hardness of work.

m = IxA/FxZ

Where, F = faraday's constant = 96,500 Columns = 26.8 amp-hours,

I = current flowing in amperes,

Z = Valances of metal dissolved,

A = atomic weight of material in grams,

m = Material removal rate in grams per second

Some Advantages

No mechanical and cutting force

There is no heat affected zone

It is very accurate.

No material corrosion

It provides smooth surfaces

Some Disadvantages

It needs solution usage

Keeping the solution conductivity constant

More expensive than conventional machining

Chemical attack by electrolytes

Material has to be electrically conductive

Some Applications

Applications are used for highly sensitive working areas like; electronic, air and space industries.The most common application of ECM is high accuracy duplication. Because there is no tool wear, it can be used repeatedly with a high degree of accuracy.

.