Non-expendable mold casting

Non-expendable mold casting uses molds that are intended for permanent use over long runs. The molds are generally metal, but the method of performing the casting differs greatly from many expendable methods. It differs from expendable processes in that the mold need not be reformed after each production cycle. This technique includes at least four different methods: permanent, die, centrifugal, and continuous casting. This form of casting also results in improved repeatability in parts produced and delivers Near Net Shape results.

Permanent mold casting

Permanent mold casting uses metal to form a mold, so it is a much less expendable form of casting. The metal molds can be reused many times, but are only semi-permanent despite their name. .Main articles: Permanent mold casting, low-pressure permanent mold casting and vacuum permanent mold casting.

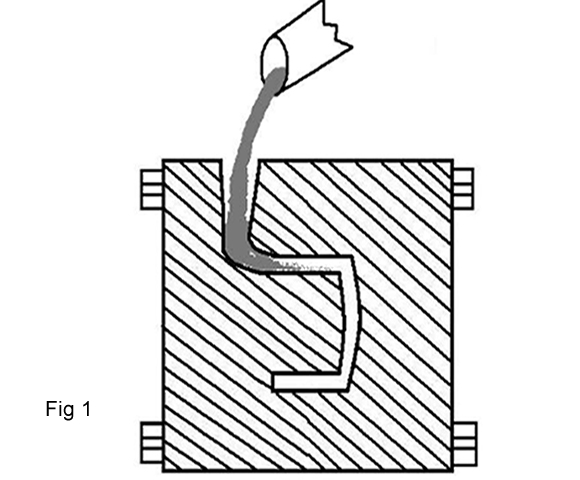

The most common process uses gravity to fill the mold (fig 1). However, gas pressure or a vacuum are also used. A variation on the typical gravity casting process, called slush casting, produces hollow castings. Common casting metals are aluminum, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds. Permanent molds, while lasting more than one casting still have a limited life before wearing out.

Permanent mold casting is typically used for high-volume production of small, simple metal parts with uniform wall thickness. Non-ferrous metals are typically used in this process, such as aluminum alloys, magnesium alloys, and copper alloys. However, irons and steels can also be cast using graphite molds. Common permanent mold parts include gears and gear housings, pipe fittings, and other automotive and aircraft components such as pistons, impellers, and wheels. Instead of using sand as the mold material, a metal is used as a mold. Typically cast iron or Meehanite (a dense cast iron) is used as the mold material and the cores are made from metal or sand. Cavity surfaces are coated with a thin layer of heat resistant material such as clay or sodium silicate.

The permanent mold casting process consists of Mold preparation, Mold assembly, Pouring, Cooling and Trimming. The permanent mold casting process consists of the following steps:

Mold preparation:

First, the mold is pre-heated to around 150-260°C to allow better metal flow and reduce defects. Then, a ceramic coating is applied to the mold cavity surfaces to facilitate part removal and increase the mold lifetime.

Mold assembly :

The mold consists of at least two parts - the two mold halves and any cores used to form complex features. Such cores are typically made from iron or steel, but expendable sand cores are sometimes used. In this step, the cores are inserted and the mold halves are clamped together.

Pouring:

The molten metal is poured at a slow rate from a ladle into the mold through a sprue at the top of the mold. The metal flows through a runner system and enters the mold cavity.

Cooling:

The molten metal is allowed to cool and solidify in the mold. Mold opening - After the metal has solidified, the two mold halves are opened and the casting is removed.

Trimming:

During cooling, the metal in the runner system and sprue solidify attached to the casting. This excess material is now cut away.

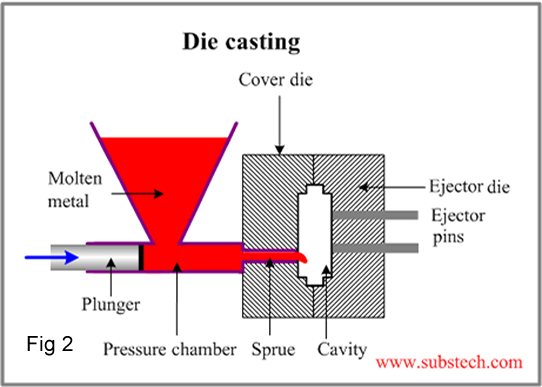

Die casting

The die casting process forces molten metal under high pressure into mold cavities (which are machined into dies). Most die castings are made from nonferrous metals, specifically zinc, copper, and aluminium-based alloys, but ferrous metal die castings are possible. The die casting method is especially suited for applications where many small to medium-sized parts are needed with good detail, a fine surface quality and dimensional consistency fig2).

Die casting process consists of the following steps:

Step 1: Clamping is the preparation and clamping of the two halves of the die.

Step 2: Injection: The molten metal, which is maintained at a set temperature in the furnace, is next transferred into a chamber where it can be injected into the die.

Step3: Cooling: The molten metal that is injected into the die will begin to cool and solidify once it enters the die cavity.

Step4: Ejection: After the predetermined cooling time has passed, the die halves can be opened and an ejection mechanism can push the casting out of the die cavity.

Step5: Trimming: During cooling, the material in the channels of the die will solidify attached to the casting. This excess material, along with any flash that has occurred, must be trimmed from the casting either manually via cutting or sawing, or using a trimming press.Equipment.

There isn't one single process that can suit every project. Each project is different therefore multiple solutions offers for all die casting needs.

Generally, there are two types of die casting machines a hot chamber machine and cold chamber machine.

Hot-Chamber Die Casting

Used for zinc, some magnesium alloys, and other low-melting, hot-chamber die casting is a great option for alloys that do not readily attack and erode metal pots, cylinders, and plungers.

Cold-Chamber Die Casting

Better suited for metals with higher melting points than Zn and Mg such as aluminium, during cold-chamber die casting, metal is liquefied and then ladled into a cold chamber where a hydraulically operated plunger pushes the metal into the die.

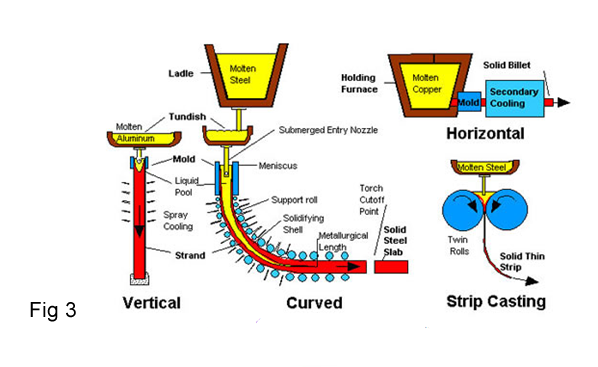

Continuous casting

Molten metal is poured into an open-ended, water-cooled copper mold, which allows a 'skin' of solid metal to form over the still-liquid centre. The strand, as it is now called, is withdrawn from the mold and passed into a chamber of rollers and water sprays; the rollers support the thin skin of the strand while the sprays remove heat from the strand, gradually solidifying the strand from the outside in. After solidification, predetermined lengths of the strand are cut off by either mechanical shears or travelling oxyacetylene torches and transferred to further forming processes, or to a stockpile. Cast sizes can range from strip (a few millimetres thick by about five metres wide) to billets (90 to 160 mm square) to slabs (1.25 m wide by 230 mm thick). Sometimes, the strand may undergo an initial hot rolling process before being cut. Continuous casting is used due to the lower costs associated with continuous production of a standard product, and also increases the quality of the final product. Metals such as steel, copper and aluminium are continuously cast, with steel being the metal with the greatest tonnages cast using this method. Continuous casting is a refinement of the casting process for the continuous, high-volume production of metal sections with a constant cross-section.

The continuous casting process for steel is shown in Figure 3, molten steel flows from a ladle, through a tundish into the mold. The tundish holds enough metal to provide a continuous flow to the mold, even during an exchange of ladles, which are supplied periodically from the steelmaking process. The tundish can also serve as a refining vessel to float out detrimental inclusions into the slag layer. If solid inclusion particles are allowed to remain in the product, then surface defects such as "slivers" may form during subsequent rolling operations, or they may cause local internal stress concentration, which lowers the fatigue life. To produce higher quality product, the liquid steel must be protected from exposure to air by a slag cover over the liquid surface in each vessel and by using ceramic nozzles between vessels. If not, then oxygen in the air will react to form detrimental oxide inclusions in the steel.

Once in the mold, the molten steel freezes against the water-cooled walls of a bottomless copper mold to form a solid shell. The mold is oscillated vertically in order to discourage sticking of the shell to the mold walls. Drive rolls lower in the machine continuously withdraw the shell from the mold at a rate or "casting speed" that matches the flow of incoming metal, so the process ideally runs in steady state. The liquid flow rate is controlled by restricting the opening in the nozzle according to the signal fed back from a level sensor in the mold.

Centrifugal casting

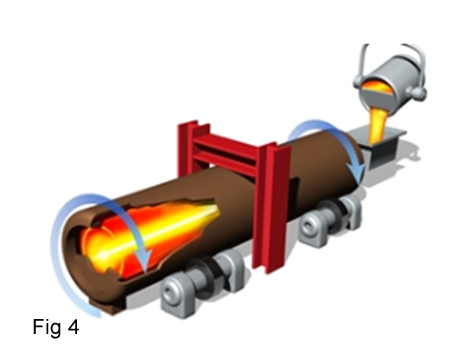

Centrifugal casting is both gravity- and pressure-independent since it creates its own force feed using a temporary sand mold held in a spinning chamber at up to 900 N (90 g). Lead time varies with the application. Semi- and true-centrifugal processing permit 30-50 pieces/hr-mold to be produced, with a practical limit for batch processing of approximately 9000 kg total mass with a typical per-item limit of 2.3-4.5 kg(fig 4).

Industrially, the centrifugal casting of railway wheels was an early application of the method developed by German industrial company Krupp and this capability enabled the rapid growth of the enterprise. Small art pieces such as jewelry are often cast by this method using the lost wax process, as the forces enable the rather viscous liquid metals to flow through very small passages and into fine details such as leaves and petals. This effect is similar to the benefits from vacuum casting, also applied to jewelry casting.

Centrifugal casting, sometimes called rotocasting, is a metal casting process that uses centrifugal force to form cylindrical parts. This differs from most metal casting processes, which use gravity or pressure to fill the mold. In centrifugal casting, a permanent mold made from steel, cast iron, or graphite is typically used. However, the use of expendable sand molds is also possible.

In the centrifugal casting process, molten metal is poured into a spinning die. The die can be spinning either on a vertical or horizontal axis depending on the configuration of the desired part. Ring and cylinder type shapes are cast vertically; tubular shapes are made with the horizontal centrifugal process. Either process may be used to produce multiple parts from a single casting. External structures and shaping can be cast in place to significantly reduce post-processing including machining or fabrication.