Soldering

Soldering is the process of joining two metal objects together by third soft metal alloy which is called solder. Solder is a metal alloy which melts at a lower temperature than the metals being soldered. Two types of solder are commonly used. One is a soft solder, which is an alloy of tin and lead. The other is a hard solder, which is an alloy of copper and Zinc. This usually called spelt or silver solder.

Solder is used for electronics is a metal alloy, made by combining tin and lead in different proportions. You can usually find these proportions marked on the various types of solder available. With most tin/lead solder combinations, melting does not take place all at once. Fifty-fifty solder begins to melt at 183 o C, but it's not fully melted until the temperature reaches 216 o C. Between these two temperatures, the solder exists in a plastic or semi-liquid state.

The plastic range of a solder varies, depending upon the ratio of tin to lead. With 60/40 solder, the range is much smaller than it is for 50/50 solder. The 63/37 ratio, known as eutectic solder has practically no plastic range, and melts almost instantly at 183 o C .

The solders most commonly used for hand soldering in electronics are the 60/40 type and the 63/37 type. Due to the plastic range of the 60/40 type, you need to be careful not to move any elements of the joint during the cool down period. Movement may cause what is known as disturbed joint. A disturbed joint has a rough, irregular appearance and looks dull instead of bright and shiny. A disturbed solder joint may be unreliable and may require rework.

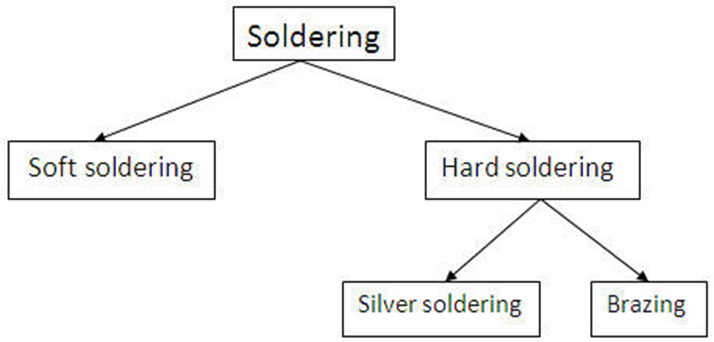

Types of Soldering

Figure 1 shows the types of soldering:

Soft soldering

It is a process for joining small intricate parts having low melting points which damages when soldering process is carried out at high temperature. It uses tin-lead alloy as filler material. The melting point of the filler material should be below 400 oC . It uses gas torch as the heat source.

Hard soldering

In this process, hard solder connects two pieces of metals by expanding into the pores of the work piece opened by high temperature. The filler material possess high temperature above 450 oC It comprises of two parts namely silver soldering and brazing.

Silver soldering

It is a clean process useful for fabricating small fittings, doing odd repairs and making tools. It uses an alloy containing silver as filler material. Silver provides free flowing characteristics but silver solder is not good at gap filling hence, different fluxes are recommended for precised silver solder.

Brazing

Brazing is a process of joining two pieces of base metals by creating melted metallic filler that flows by capillary attraction across the joints and cools to form a solid bond through atomic attraction and diffusion. It creates an extremely strong joint. It uses brass alloy as filler material.