Shielded Metal Arc Welding (SMAW)

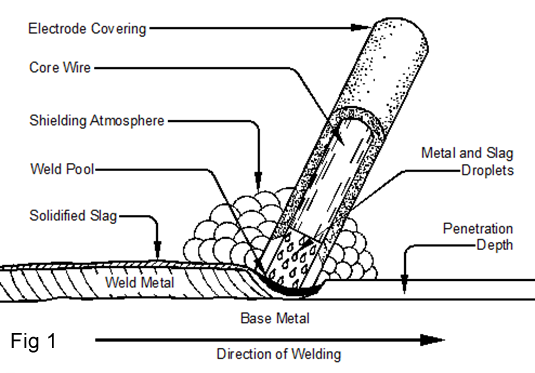

It is known as manual metal arc welding, stick welding, or electric arc welding, is the most widely used of the various arc welding processes. Welding is performed with the heat of an electric arc that is maintained between the end of a coated metal electrode and the work piece. The heat produced by the arc melts the base metal, the electrode core rod, and the coating. As the molten metal droplets are transferred across the arc and into the molten weld puddle, they are shielded from the atmosphere by the gases produced from the decomposition of the flux coating. The molten slag floats to the top of the weld puddle where it protects the weld metal from the atmosphere during solidification (fig1). The electrode core provides most of the weld filler metal. When the electrode is moved along the workpiece at the correct speed the metal deposits in a uniform layer called a bead. The Stick welding power source provides constant current (CC) and may be either alternating current (AC) or direct current (DC), depending on the electrode being used. The best welding characteristics are usually obtained using DC power sources.

The power in a welding circuit is measured in voltage and current. The voltage (Volts) is governed by the arc length between the electrode and the workpiece and is influenced by electrode diameter. Current is a more practical measure of the power in a weld circuit and is measured in amperes (Amps).The amperage needed to weld depends on electrode diameter, the size and thickness of the pieces to be welded, and the position of the welding. Thin metals require less current than thick metals, and a small electrode requires less amperage than a large one. It is preferable to weld on work in the flat or horizontal position. However, when forced to weld in vertical or overhead positions it is helpful to reduce the amperage from that used when welding horizontally. Best welding results are achieved by maintaining a short arc, moving the electrode at a uniform speed, and feeding the electrode downward at a constant speed as it melts.

SMAW is well known for its versatility because it can be used in all welding positions, and in both production and repair welding situations. It is one of the simplest welding processes in terms of equipment requirements and can be easily operated in remote locations. However, it is strictly a manual welding process that generally requires a high welder skill level. In addition, it is typically restricted to material thickness greater than approximately 1.6 mm.