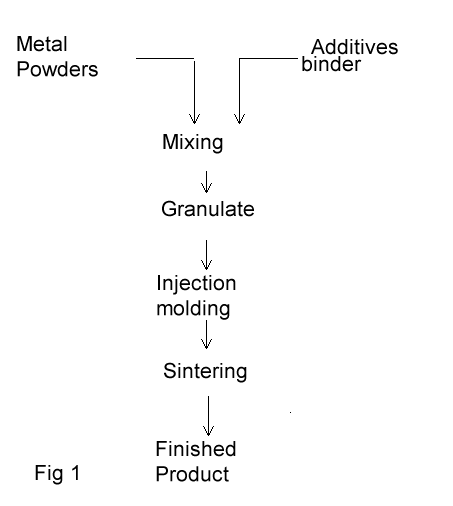

Metal injection molding (MIM) process

Injection Metal Molding (MIM), sometimes called Powdered Injection Molding (PIM), is an advance metal forming technique that uses injection molding equipment for manufacturing both simple and complex metal parts to tight tolerances. The standard PM process is to compact a lubricated powder mix in a rigid die by uniaxial pressure, eject the compact from the die, and sinter it. Although MIM can be utilized across a wide range of components, the best applications are typically small in overall size and less than 100 grams in weight. The process can replace other metal forming techniques such as investment casting and machining. A wide variety of metal alloys including various steels, titanium, copper, nickel, and more are available for the MIM process.

The metal injection moulding (MIM) process offers the following advantages such as:

- Lower overall product cost

- High complexity shape capability

- More efficient use of material and processes

- Less material waste

- Repeatability

- Excellent mechanical properties

- Tailored solutions using unique materials

- Reduced production time compared with investment casting

- Properties equivalent to wrought alloys

- Wide range of pre-alloys and master alloys available

The process steps involve combining metal powders with wax and plastic binders to produce the "feedstock" mix that is injected as a liquid into a hollow mold using plastic injection molding machines (fig1). The "green part" is cooled and de-molded in the plastic molding machine. Next, a portion of the binder material is removed using solvent, thermal furnaces, catalytic process, or a combination of methods. The resulting, fragile and porous (2-4% "air") part, in a condition called "brown" stage, requires the metal to be condensed in a furnace process called Sintering. MIM parts are sintered at temperatures nearly high enough to melt the entire metal part outright (up to 1450oC, at which the metal particle surfaces bind together to result in a final, 96-99% solid density. The end-product MIM metal has comparable mechanical and physical properties with parts made using classic metalworking methods, and MIM materials are compatible with the same subsequent metal conditioning treatments such as plating, passivating, annealing, carburizing, nitriding, and precipitation hardening.